Inspired by the antifreeze proteins found in arctic organisms, a team of scientists from the University of Colorado Boulder recently came up with a type of high-strength concrete that is highly resistant to the damaging effects of the yearly freeze-thaw cycle. The concrete is said to withstand up to 300 such cycles.

People living in high latitude, snowy regions deal with freeze-thaw damages to their properties on a daily basis. Concrete is no exception. Water within the concrete expands when frozen, which results in frost heaving, a phenomenon where repeated freeze-thaw cycles create and deepen micro-fractures in the concrete. Frost heaving is extremely harmful to concrete, as the damage it inflicts is irreversible.

This phenomenon commonly occurs on roads and bridges. Scientists from as early as the 1930s have tried to come up with various ways to mitigate the damages of frost heaving. One such solution involves injecting tiny bubbles into the cement as it is being mixed to create more space inside the concrete where water can expand once frozen into ice, reducing the structural stress that is exerted as a result.

But this solution is not without its drawbacks, namely, reduced structural integrity and increased permeability, the latter of which makes concrete porous enough for damaging foreign objects, such as salt and other chemicals, to enter and thus degrade the steel beams inside. And that’s just the tip of the iceberg when it comes to the micro-bubble solutions’ compromises. In light of this, the team from Boulder may have arrived at a superior alternative.

As previously mentioned, the Boulder team took inspiration from the antifreeze proteins found in arctic organisms. These proteins contain peptides that limit the formation of ice crystals and allow arctic organisms to survive in extreme cold. Unfortunately, antifreeze proteins cannot be incorporated into concrete, mostly because the latter’s extremely alkaline nature (with a pH value of over 12) is not peptide-friendly. That is why the Boulder team instead decided to opt for a synthetic compound that duplicates the peptide’s function while able to survive in alkaline conditions. The team found a solution in PEG-PVA (polyethylene glycol-polyvinyl alcohol).

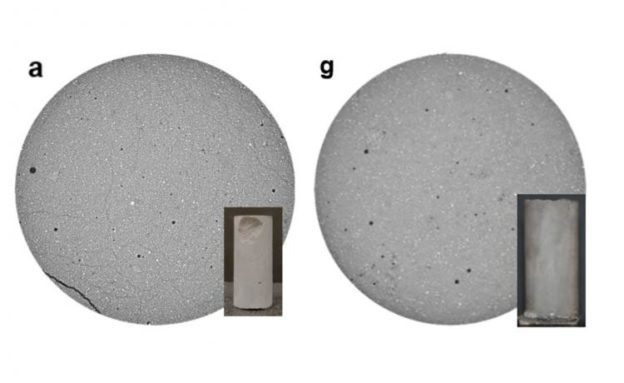

Adding the PEG-PVA compound to cement reduces the size of ice crystals in the resultant concrete by as much as 90%. According to the team’s findings, published in the Cell Reports Physical Science journal, the PEG-PVA-added concrete was completely unaffected after 30 freeze-thaw cycles, while it retained a high degree of resistance even after 300 cycles. Furthermore, this type of concrete is stronger and less permeable than micro-bubble-injected concrete, thereby making it last longer come wintertime.

The Boulder researchers are currently continuing to explore the viability and economic benefits of PEG-PVA, with an expected date of commercialization five to 10 years from now. Wil Srubar, assistant professor at the University of Colorado Boulder’s College of Engineering and Applied Science and head of the research team, believes that the PEG-PVA compound, though wildly divergent from existent materials that have been in use for more than 70 years, is a step in the right direction and a catalyst for more exciting developments in concrete additive technology.